About Us

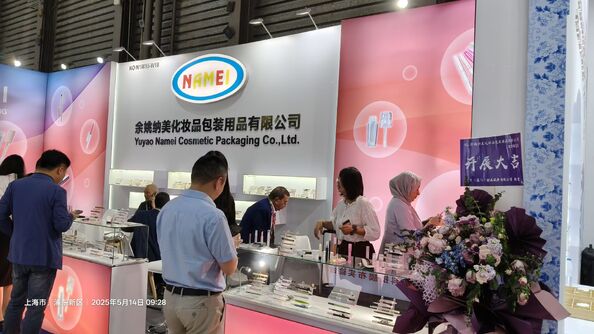

Yuyao Namei Cosmetics Packaging Co., Ltd.

Yuyao Namei Cosmetics Packaging Co., Ltd. is a specialized manufacturer of plastic cosmetic brush packaging. Since its establishment, the company has evolved from producing a single type of automatic packaging eyebrow pencil to offering a wide range of cosmetic packaging solutions. Our product line now includes cotton core liquid eyeliners, direct liquid eyeliners, automatic eyebrow pencils, sealed automatic eyeliners, automatic lipstick pens, automatic concealer pens, eyeshadow pens, sealed ...